Welcome to Ghost In The Embroidery Machine, where you’ll get all the tips and tricks you need to become a dynamic digital embroiderer, thanks to the wit and wisdom of Erich Campbell!

If you enjoy digitising designs and producing them with your embroidery machine, you might think about transitioning to a professional career in the field, here are the top six things I’ve learned to help you on your way:

- Running a business can be boring.

- Focus, focus, focus.

- Know the real cost of your work.

- Be audacious.

- Get good at selling.

- Establish boundaries.

That’s my thesis in a nutshell but allow me to dive deeper to enlighten you further.

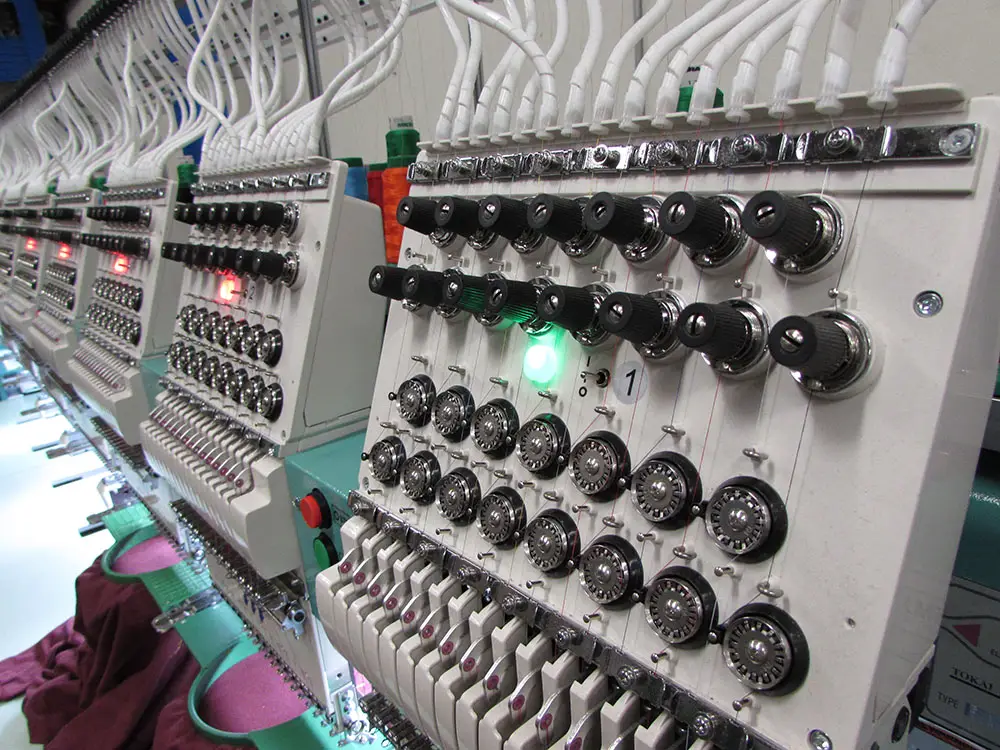

If you’ve been reading my work a while, you’ll know that I started my machine embroidery adventure firmly placed in the commercial world; the first machines I ever operated were large, industrial hardware; 12 head ‘vintage’ Tajima machines with a forest of Madeira cones bristling from their backs. I started as a guy who boxed shirts between classes at the university, graduated to operating machines, and then taught myself to digitize on a disused old system. Though I was always working to inject my own artistic sensibilities and experimented avidly in my own time, I knew that every step of the way, I was there to make the needles move, keep things efficient as well as aesthetically pleasing, and ultimately, to make a profit.

Many of my commercial embroidery friends, however, came to their employment via a very different route; starting as machine embroidery hobbyists and artists who later decide to move into the business sphere. Their first experiences were with single-needle home machines, changing colors manually throughout each design, running and attending to one piece at a time, and spending these dedicated hours as entertainment rather than employment, while simultaneously throwing themselves completely to their art and slavishly working to learn things for their own expansion. They are natural artistic experimenters and wizards of multimedia, as the journey of doing the work was as rewarding as the result, and their early work was more concerned by what they could make their machines do, not how they achieved it or how long a piece took to create.

With many years under my belt writing and teaching embroiderers of all manner of backgrounds, I’ve found that the particular path from hobbyist to business person has the same pitfalls for many of those who walk it. As I have learned greatly from the willingness of the home embroiderers to experiment and stretch the boundaries of what we can technically achieve, I hope to help those hobbyists in transition to bridge the gaps that keep them from becoming full-fledged businesspeople. To that end, here are the top 6 things I’ve repeatedly told my hobby-to-business friends when they are faced with such dilemmas.

Be ready for the ‘boring’ bits.

If you aren’t a businessperson, don’t like talking about or handling money matters, can’t stand sales or marketing, or don’t like serving people, you had better find a partner who does. If you want to get paid, you will shuffle some (real or virtual) paper in the process.

Focus, focus, focus.

It’s easy to be pulled in myriad directions by each new project that tickles your creative fancy, but though it’s good to experiment, not every project, prospective product, or technique is meant to be a part of your business. Define your customer, define your specialty, play to your strengths, and prune away the things that don’t fit. This is especially true if the new venture you want to pursue requires new equipment; if you aren’t profitable with the equipment you have and your new venture is less than a sure moneymaker, give the appropriate attention to your core business or technique instead of buying into the new fun thing. There are times when new equipment or decoration processes will enhance your business, but it’s not nearly as frequent as the times when a shiny new toy will enthrall you. I know a stable of embroiderers with unnecessary equipment gathering dust in their studios who wish they had been more focused and purposeful with their growth.

Know what it costs to do the work.

So many early embroiders underprice their work because they feel unsure of their skills, but do so at the peril of their businesses. This is especially true when they’ve made capital investments and have leases to pay on their equipment. You need to know what it costs to run your machine, how much your materials run and how much each job may use, how much time is involved in a given job, and calculate a price that not only accounts for all these variables but that pays you a wage for the work you do.Know your overhead and price accordingly. Better yet, price on the value you provide and not the work you do; if a unique proposition exists to give value to the client and they stand to gain from your work, there’s no reason they can’t share the wealth.

Have the audacity to ask for what you are worth.

Don’t undervalue your labor or discount it at random. Value your work and expertise and realize that you are exchanging your expert technical knowledge, creativity, and the use of uncommon machinery and supplies for the price you are asking. If you believe in your work, believe that it is worth paying for.

Be ready to sell.

Sales isn’t a dirty word; if you are doing good work, sharing it, selling it, and telling people about it is wholly desirable. After all, if you believe in your work, you are doing the world a disservice if you don’t put it in front of them and show them what they might be missing; provide real value and sales doesn’t have to be shifty.

Set firm boundaries.

Especially in the home-based business arena, it’s hard to physically and mentally separate your business and home lives. Start early by fencing off business hours, using a service or a second phone to have a business-only point of contact, and if possible, by physically keeping your work in a designated work space. Even if it’s a temporary space, don’t let the work bleed into other areas- it harms your life and the life of the business- and it goes both ways. Don’t let other personal pursuits into the business time. Clock into your job, and just as importantly, clock out and recharge!

This is a topic that I intend to revisit from many angles. The hobbyists have so much to offer the commercial industry and I think that those of us who come from the professional decoration side should listen, learn, and return the favor. I’d love to hear what you’ve learned, if you too have made the transition to pro.

Erich Campbell is an award-winning machine embroidery digitizer and designer and a decorated apparel industry expert, frequently contributing articles and interviews to embroidery industry magazines such as Printwear, Stitches, and Wearables as well as a host of blogs, social media groups, and other industry resources.

Erich is an evangelist for the craft, a stitch-obsessed embroidery believer, and firmly holds to constant, lifelong learning and the free exchange of technique and experience through conversations with his fellow embroiderers. A small collection of his original stock designs can be found at The Only Stitch