Patches are one of the coolest forms of machine embroidery, a great way of recognising your favourite band, team or just making your clothes and bags that bit more personal. But how do you make them?

The steps to make your own custom embroidery patches are:

- Use a stock blank for quick results, or

- Use water soluble backing

- Hold the elements together with placement stitches

- Use tacking stitches

- Stitch the individual design elements by colour

- Dissolve the backing

Let’s dive into this process a bit more, as it might seem daunting but if you take your time you’ll unlock massive potential for personalising your world with patches!

What Are Embroidery Patches?

One of the first ways many of us come into contact with machine embroidery is through the world of patches. Whether it’s the classic merit badge, the manifold patches of militaria or the roughly tacked-on band logos on our brutalized school-age jackets and bags, patches remain one of the most visible and well-loved ways to display machine embroidery.

An embroidery patch is created using thread and backing fabric and features a design or logo that identifies a community. There is a long tradition of hand embroidered patches but developments in digitized machine embroidery have made them accessible to the masses.

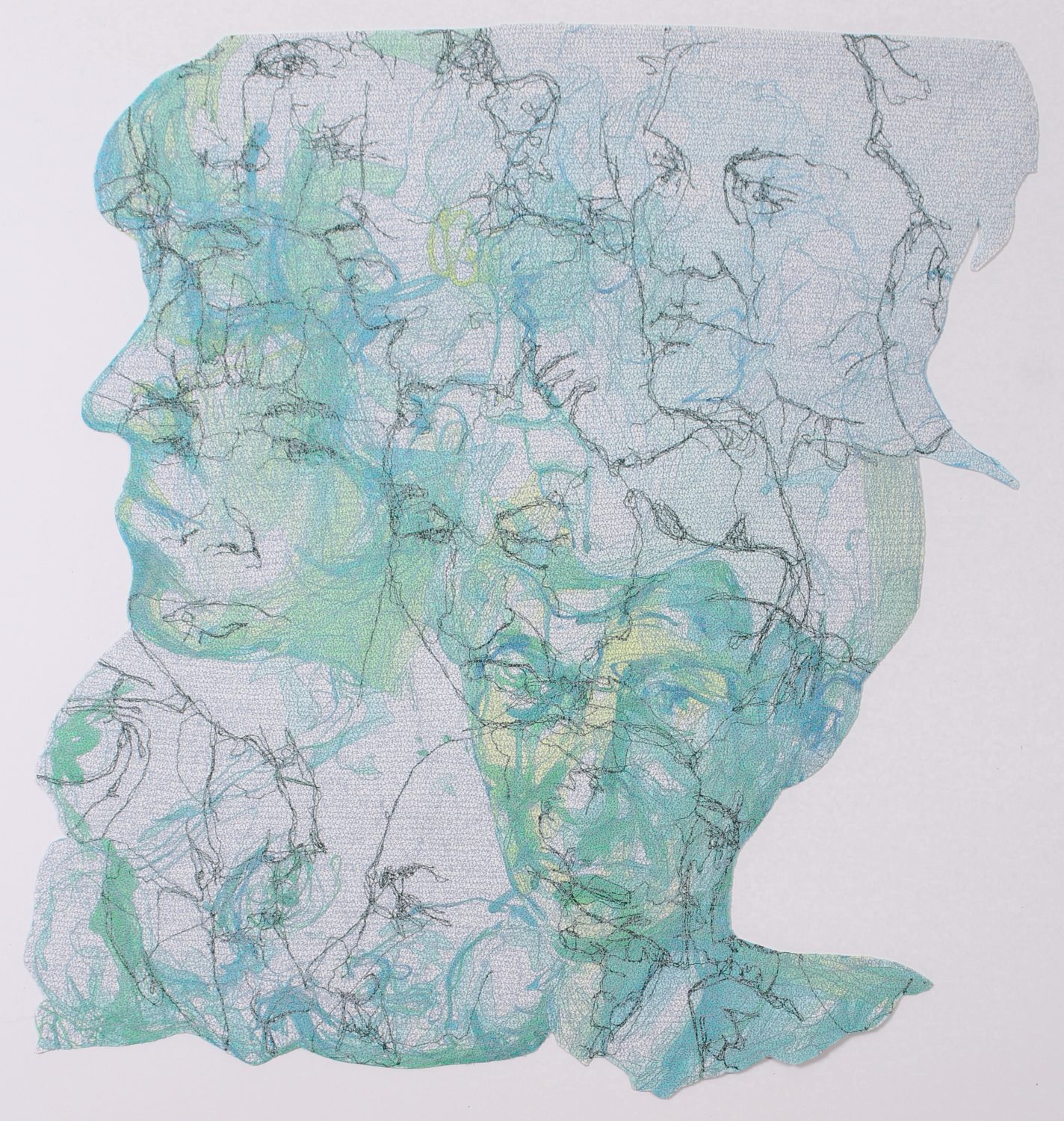

As impressive as they look, it’s actually a fairly simple matter to produce your own custom patch on any embroidery machine. I rekindled my love of patches after making the patch-styled designs in this post. Though I made real patches commercially with great regularity, designing these slight subversions of the military style, even though they were direct embroidery, really got me excited to make custom patches for myself again.

Using A Stock Blank Patch

The ‘proper’ patches we all know and love require the use of a special merrowing machine to make that tough, bound edge. If that’s an absolute must for your project and you don’t mind working with standard shapes, you can always order ready-made blanks. They are available in a wide variety of shapes and color combinations and provide a stable, smooth surface.

Setting up for a stock blank is as easy as creating an outline shaped as the blank that runs before your design. This placement line makes sure your design lands on the patch just where you expect. Aside from the optional addition of a post placement run of basting stitches just inside the edge to temporarily secure it during embroidery, no further design editing is usually necessary.

How Do I Embroider Stock Patch Blanks?

To embroider stock patch blanks:

- Hoop some sturdy tearaway backing

- Run the placement outline

- Adhere the blank with a quick shot of light embroidery-specific spray adhesive and run the design as usual.

- After the run, remove any basting stitches and carefully tear the backing away to reveal a sturdy, professional-looking patch.

Using a stock blank can work in a pinch, but although there is a plethora of colours, sizes, and shapes on the market, ready-made blanks force you to tailor your design to fit the area/aspect ratio of a given emblem and the palette of colours is still limited.

For that reason, I almost always choose to forgo the merrowed edge to create custom-cut patches.

How To Make Your Own Custom Patch

You can make patches in nearly any shape you can imagine, using any thread for edging, from any number of base materials. Though speciality equipment like plotter/cutter machines and purpose made materials greatly speed their creation, you can embark on a custom project with little more than a sharp, pointed scissor and water-soluble backing.

If you are a plotter-user or a laser-cutter wizard, I don’t need to tell you how you can cut materials by feeding vector art into your favourite machine. Needless to say, whether you start with a technological solution or you utilise patterns for manual cutting, or work entirely in the hoop, the process of production is within your reach.

In all cases, creating a custom-cut piece starts with much the same method outlined for stock patches. The only difference is that you’ll be edging the patch with your embroidery machines, meaning you need more than a placement line in your files.

You have to find or digitise your shape with the placement line, a zigzag tack-down stitch just narrower than you want the finished edge, and finish with a dense satin-stitch border about 3 mm wide, and overall larger by just under a millimetre than the base material you’ve cut.

For an extra-clean finish, use a colour-matched bobbin thread for the final border for that wrap-around look.

Using Water Soluble Backing

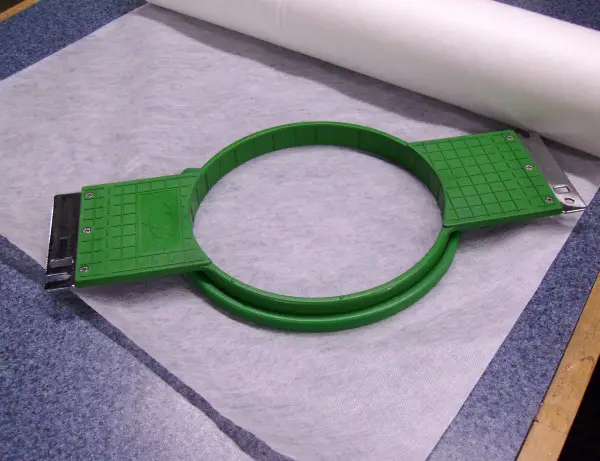

Both pre-cut and in-the-hoop embroidery patches start with solid water-soluble backing. I recommend a ‘fibrous’ water-soluble backing rather than a film. The thin film meant as topping for textured garments will not be sturdy enough to hold up to heavy stitching without tearing or loosening.

If you can’t find fibrous water soluble backing, be sure to use layers of the thick films specifically marketed for the creation of patches or badges.

Create Your Placement Stitches

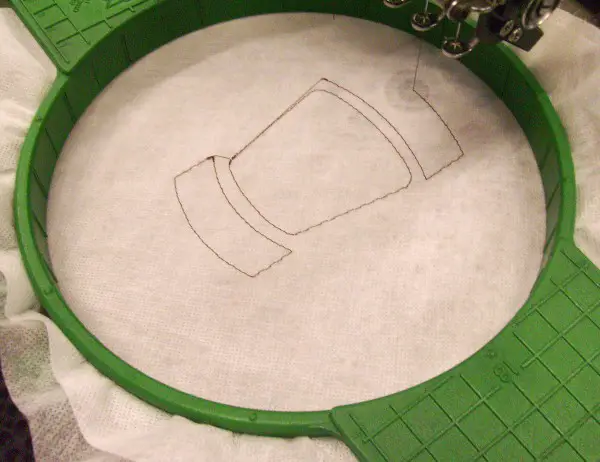

The easiest way to manage the stitching steps on your machine is to put each element on a new colour change in your software so that the machine stops between stages.

With pre-cut material, the first colour of the design should be used as a standard placement line, after which you should lightly adhere your cut piece to the backing.

For in-the-hoop hand-cut patches, place a piece of fabric larger than your finished area on the backing before you run the outline. After the initial outline runs, you can remove the hoop from the machine, leaving the backing hooped, then carefully cut away the excess patch material outside of the line.

Use Tacking Stitches

From here out, the processes converge.

The next step is to sew that wide zigzag tacking element. After your material is married to the backing, you’ll stitch your central design, leaving the last colour change for the satin-stitch run around the edges. This makes it less likely that the cutting action of the final border’s dense stitching will release the piece prematurely from the backing.

Dissolve The Backing Of Your Patch

Once this is finished, all you have to do is dissolve the backing.

To save time in the rinse stage, cut away as much of the excess water-soluble backing as you can from your patch before rinsing.

Follow the instructions for removal that the manufacturer recommends for your specific backing. My favourite backing melts away readily with a simple rinse in running water. Once it rinses clean (no residue or foam, or it may be stiff/sticky later), you’ll have a clean finished edge with thread cleanly wrapping to the back of the emblem.

For such a simple process, patch making offers a world of possibilities for expression. Moreover, there’s nothing like a patch for a non-sized, easily shipped way to make wearable art that you can trade with your fiber-art friends.

For me, the feeling of being a part of and being able to influence and tweak that language of fandom, affiliations, clubs and achievements that seemed like the secret realms of some initiated few when I was a kid keeps me coming back to emblems again and again.

Related Questions:

Is It Better To Sew Or Iron On A Patch?

Sewing embroidery patches on to a garment is a better long term choice, as it binds the patch to the surface and you would need to cut the sewn threads to remove it. Iron-on patches are convenient and do a good job of holding the patch to the fabric, but their adhesion will fade over time and with washing.

What Material Can You Sew Patches Onto?

Patches can be sewn on to almost any fabric, but sturdy fabrics like Denim, Cotton and Leather work best, and flexible fabrics like Nylon, Rayon and Spandex may get damaged by stitched patches.

What Material Is Best For Iron-On Patch Making?

As with sewn patches, denim and cotton are best suited for iron-on patches, and you want your base fabric to be at least as thick as the patch material. Iron-on patches will not adhere to leather, or plastic fabrics like nylon.