There is a little-known truth outside the textile world that I am going to share right now: Threads are made, not born. Whether the thread comes from natural or man-made materials, there is some level of manufacturing involved to bring the final product to your hands and needles. People and machines of some sort were involved in creating, dyeing, or preparing the thread you use.

I say this with a smile because, as a thread manufacturer for 40+ years, we get quizzical looks when we tell someone we make thread. “What? You MAKE it?” You can actually see on their faces that they are trying to wrap their minds around the concept. “Thread? Made…? Someone MAKES thread? How do you MAKE thread?” (Sometimes we have to explain what THREAD actually is…) At needlework trade shows, we get requests for different kinds of threads or colors, such as, “I need a thread shade between early fall maple leaf and ripe pumpkin” —and they need it right away. Somewhere along the line, however, it has to be made.

Some companies buy thread already made and repackage it. Some companies buy thread and dye it. We manufacture thread in a small factory in West Virginia. Alas, neither magic nor elves are involved. However, there is manufacturing—“something made from raw materials by hand or by machinery” (Merriam-Webster)—researching, developing, transforming, testing, and creating. I’ve seen it first-hand, and the process is actually quite complicated. And impressive? Wow, yeah. Amazingly cool. The factory isn’t just a building, it is made of people who use technology to create incredibly beautiful threads.

We love factory tours. I don’t think there’s a potato chip or pretzel factory on the U.S. east coast that I haven’t visited. Doug Kreinik has been to a toilet factory, a chocolate factory, and a carpet factory among many others. It’s fun to see how things are made.

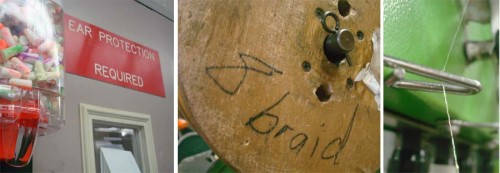

The Kreinik thread factory isn’t open to the public, but we can give a virtual tour through these photos of my recent visit. This year, we had to replace several machines and build some new ones. Yes, Mr. Kreinik senior (founder of the company) and current owner Doug (his son) actually built some of the thread machines we have today, so it’s not unusual to find Doug putting together his own equipment. Creativity, innovation and “making things” is part of the Kreinik culture.

Take a look at the photos here for a sneak peek behind the scenes of the Kreinik thread factory—seen publicly for the first time. Imagine the rhythmic sounds of wheels in motion, magnified just a bit from our early days of making thread in the house basement. Imagine 20 or so of the good people of Parkersburg, West Virginia, running those machines, plus skeining, kitting, labeling, packing and shipping the products. Visit www.kreinik.com to see the threads, the end result of the whole creative process. And, enjoy; we made these for you.

Contact Kreinik to share your questions, comments, or suggestions for new threads.